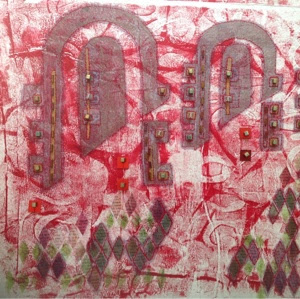

I don't know if you can tell from this photo, but that jump suit (part of Son No 1 Autumn Winter 2013 collection) is made from a PVC covered printed cotton. It's a great technique and one that definitely offers all sorts of opportunities for things like bags, natty dog coats or anything else that needs a bit of protection.

The ingredients:-

- Fabric to be laminated. We used a screen printed cotton drill but I can't see why this technique would not work with any cotton. I would like to try it with wool fabrics (perhaps a tweedy one - always thinking of dog coats) but haven't yet. If anyone does, perhaps you could report back.

- Bonda Web (or I think it is called Wunder Under in the States) - the stuff that comes mounted on a thin but stiff paper backing, which you melt onto fabric, pull the backing off, and then stick another fabric on top.

- Clear PVC sheeting - now if you live anywhere near the Goldhawk Road in Shepherds Bush West London then many of those wonderful shops sell this stuff. Failing that you can get it on line. Here is one supplier I found in the UK and here is another. The picture in this second supplier is better and it certainly looks like the stuff that I bought in Shepherds Bush.

- Teflon sheets - OK now this is the secret ingredient and frankly you cannot do this without a teflon sheet. If you look there are plenty of these around. You'll find them in kitchen shops etc because their main use is to line baking trays etc. I get mine from Aldi, but a quick gander around the internet suggests that they are readily available from many places such as Lakeland Plastics. But you do need this and not the usual baking parchment or you will melt the PVC.

Now, depending on what it is you are making, you have a choice. You can either laminate the fabric before you cut it out, or you can laminate it and then cut out the pattern pieces. For the jump suit we cut out the pattern pieces in the printed drill first and then laminated them. For the Puffa Jacket (not shown) we laminated a big piece of fabric first and then quilted it and cut out the pattern piece.

Either way the technique is the same. First of all apply the bonda web to the right side of the fabric in the normal way. Let it cool before you peel off the backing paper.

Then cut a piece of PVC about the same size as your fabric (if you have already cut your fabric pattern piece out you don't have to be exact as it is very easy to trim afterwards.) Protect your ironing board and lay your PVC onto the bondawebed fabric. Spread it out with your hands as it can wrinkle and any wrinkles left will then melt as creases onto your finished piece. You know have a layer of fabric (right side up) with bondaweb already attached and a layer of PVC.

Lay your teflon sheet on top of this layer and press down with the iron - I found it easier to press down rather than move the iron around. Be very careful here as the PVC gets very hot. You will need to check how you are getting on as irons vary. What you are doing is melting the bondaweb again but also I think melting the PVC slightly - you know when it is done as the PVC and the fabric will have the same appearance as commercial PVC fabric, that is there is they are bonded together consistently across the whole piece and there are no little 'cystals' where the bondaweb has not quite melted. Be patient and steady and you will soon get into the swing of it (we did).

A couple of points. As I said, take care as the PVC gets VERY hot. Don't lift the teflon and touch it immediately - you will burn yourself. The other thing is that, even with the teflon we found that the PVC could melt (which isn't really surprising as I have just told you how hot it gets). If you need to repeat the ironing a few times to bond the glue, just be alert to this - I suggest you run a test of a bit of scrap just to see how fierce your iron is.

Also, but I did not get into the sewing much - others did that bit - you probably need a teflon foot on your machine or the plastic can stick. I have also read that talcum powder does the trick too, but have not tried it. Do report back if you have.

But what a great technique. Commercial PVC fabrics are, in my opinion, pretty naff, but so many of us produce our own fabrics now (Hilary B and Steph Redfern - you know who you are) that it is great to have a way to give them an additional twist.

And I am sorry there are not photos of the tecnique along the way. We were so full on for those few days that the camera never came out of the bag. I hope my description gives you what you need to give it a try.

Intriguing, but might be a bit warm in the wearing!

ReplyDeleteAll the boys were sweltering under the lights! And for garments, you are right. But for bags etc and to add a bit of oomph to hand printed fabrics it has to have potential, methinks!

DeleteJust wondering what to do with it next!

WOW...That is fantastic! I fell in and out of love with commercially Cotton Coated PVC - but the method you describe here looks brilliant - you can have so much more fun making your own with your own fabrics - YUMMY!!!

ReplyDeleteSo sorry I have not replied sooner. Having a hectic time in the day job just now (can get in the way!) First thanks for stopping by. And yes, give it a go! Offers wonderful scope for doing things with handpainted or dyed fabrics.

DeletePlastic carry bags are lightweight, flexible, and convenient packaging solutions used for carrying groceries, retail items, and everyday essentials. Made from durable plastic materials, they offer excellent strength and tear resistance, ensuring safe transportation of goods. Available in various sizes, thicknesses, and designs, they cater to different industry needs Plastic bag manufacturers in kolkata variants are biodegradable or recyclable, promoting environmental sustainability. Their water-resistant nature makes them ideal for protecting items from moisture. Widely used in supermarkets, shops, and households, plastic carry bags provide a cost-effective and practical solution for daily packaging needs.

DeletePlastic bags South Africa are generally inexpensive and widely available, making them accessible to people of all socioeconomic backgrounds. This is particularly important in regions with limited access to other packaging materials.

ReplyDeleteReally enjoyed reading this! You explained the topic in such a clear and engaging way—it actually made me think differently about it. Looking forward to more posts like this. Keep up the great work!

ReplyDeleteTextile Sourcing Company